Hot Demand Brings Forward Investment For Hot Isostatic Press

Hot Demand Brings Forward Investment For Hot Isostatic Press

Wallwork Group

Lord Street

Bury

Greater Manchester

BL9 0RE

United Kingdom

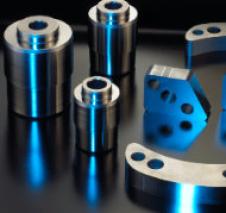

High Temperature Jigs and Castings – Independent Forgings and Alloys Improves Whole Life Performance

Independent Forgings and Alloys of Sheffield, one of the world’s largest blacksmiths, is benefitting from a castings improvement programme introduced by Wallwork Cast Alloys. The Wallwork programme will modify patterns, review alloy choice and the casting process to produce longer life castings to withstand the rigours of cyclical heating and cooling during heat treatment. This in turn will reduce energy needs, improve cycle times, and contribute to lean production and quality goals.

Independent Forgings specialise in open die forgings in carbon steel, stainless steel and alloys of nickel and titanium. These go to OEM’s in aerospace, oil and gas, nuclear, defence, power and other demanding industries.

An issue of cracking arose in stainless steel base grids and pan casings used for the heat treatment of components after forging. The original supplier was unwilling to address the issue by modifying the design or material and so Wallwork were approached for an alternative. “We examined the failed grids and casings and concluded that we could offer extended life by a design modification to the pattern and using a 55/18 nickel/chrome alloy with a higher temperature tolerance,” explained Wallwork director Peter Carpenter.

“As a heat treatment specialist, producing furnace furniture for our own factories, our working experience is part of the design process,” Peter added. “We understand the need for high strength with low thermal mass – designs that optimise component packing density, but still allow circulation space for even heating and effective quenching. Castings that retain their shape and have a good working life are vital to profitability.”

Pawel Grzesiakowski, heat treatment manager at Independent Forgings and Alloys commented, “We apply various heat treatment processes such as hardening, tempering, solution treatment, ageing and stress relieving in temperatures ranging from 420 to 1230 degrees C. All processes follow stringent quality control procedures to ensure that we meet each customer’s metallurgical requirements. The Wallwork engineer had an immediate understanding of how we use the grids and pan casings. After examination of the failed units he was able to tell us how an improved design would add strength in the vulnerable areas with a reduction in weight and an improvement in the thermal performance of the casting.”

Peter Carpenter observed, “Modern techniques can produce castings that are lighter and stronger. Less thermal mass means that the process meets its optimal temperature more quickly – reducing cycle times and so improving process productivity, reducing per component processing cost and overall energy consumption and carbon release. Extending the life of the furnace furniture also improves efficiency because less capital is tied up in the supply chain for jigs and castings”.

Wallwork Cast Alloys carry standard patterns in stock for use with Ipsen, Wild Barfield, Seco Warwick, Wellman and other heat treatment furnaces. Furnace furniture is most commonly produced in a 37/18 nickel/chrome iron alloy that retains its strength to 1050 degrees C. The company also produce furnace furniture up to 80/20 nickel/chrome castings that can operate up to 1250 degrees C.

In addition to standard and modified patterns, the company offers a custom 3D design and pattern making service to address a client’s specific production goals. Typical turnaround for castings is six to eight weeks where pattern making and customisation is required. This may be less where the pattern is already held and no modification is needed. The company has the flexibility to provide an express service to meet special circumstances.

More Information

Simeon Collins, Sales Director, Tel. +44 (0)161 797 9111 Fax. +44 (0)161 763 1861

E-mail: simeon.collins@wallworkht.com Web: www.wallworkht.com

Wallwork Heat Treatment Ltd, Lord Street, Bury, Greater Manchester, BL9 0RE, UK

Press release issued: December 14, 2012

Browse Articles

< Previous |

Next >

Wallwork Group News Archive

Halter Inn Works

Holcombe Brook

Bury

Lancashire

BL0 9SA