Environmentally Friendly Jewellery Finishing on the Table-top

Environmentally Friendly Jewellery Finishing on the Table-top

Fintek

Holcombe Brook

Bury

BL0 9SA

United Kingdom

Green Initiatives from Surface Finishing Partners

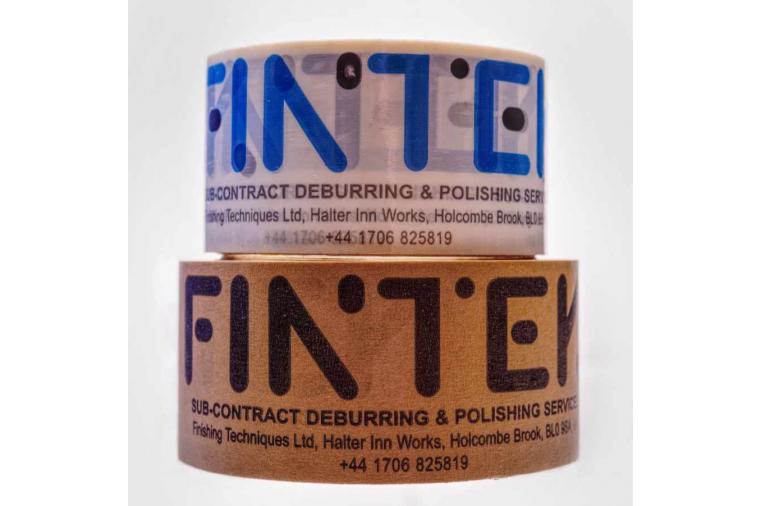

Taking a small step to reduce their usage of single-use plastic, UK metal surface finishing experts, Fintek, have changed from plastic to paper packaging tape. “I calculated that we were using nine miles of single use plastic tape per year. The paper tape is working just as well, while being biodegradable. All manufacturers have a part to play in helping to protect the environment from pollution and climate change. We will be looking at other areas of the business to see where changes can be made, however small,” explained Fintek operations manager, Jamie Phillips.

Making a significant investment in 1,992 solar panels on the sunbathed roof of their HQ is OTEC Präzisionsfinish GmbH, who manufacture and supply surface finishing machines and consumables to Fintek, “These panels can produce up to 450,000 kWh a year. This should mean that 85–90% of our entire electricity and heat consumption will come from renewable sources, allowing us to save around 55 tons of CO2 emissions each year,” explains Florian Gegenheimer, a controller and the son of managing director Helmut Gegenheimer.

The firm already has a biomass heating system and lighting has been changed to LEDs which alone should save up to 80,000kWh a year. “The environmental work Florian is leading at OTEC means customers of Fintek in aerospace, motorsports, medical devices and other precision engineering can be assured that the disc, drag and stream surface finishing machines they purchase in the UK are amongst the most ‘green’ in the industry,” added Jamie.

More Information

Jamie Phillips, Operations Manager, Tel. +44 (0)1706 283 927

Fintek, Halter Inn Works, Holcombe Brook, Bury, Lancashire, BL0 9SA

Email: jamie@fintek.co.uk Web: www.fintek.co.uk

Release issued: March 25, 2020

Browse Articles

< Previous |

Next >

Fintek News Archive

Halter Inn Works

Holcombe Brook

Bury

Lancashire

BL0 9SA